Collets and Safety Collets function very differently. Also, your 1/4″ die grinder or rotary tool will also adapt to 1/8″ shank accessories as well. You can either run a 1/8″ to 1/4″ collet adapter, or you can buy an 1/8″ collet for your specific die grinder or rotary tool. In our case, we had to buy the Milwaukee 48-66-2486 1/8″ Collet and Nut Kit that’s compatible with the Milwaukee 2485 and 2486 Die Grinders. #milwaukeetool #nothingbutheavyduty #howto

Milwaukee 1/8″ Collet and Nut Kit:

1/4″ to 1/8″ Collet Adapter (Generic):

Keep current with our great content:

YouTube:

Instagram:

TikTok:

Facebook:

Twitter:

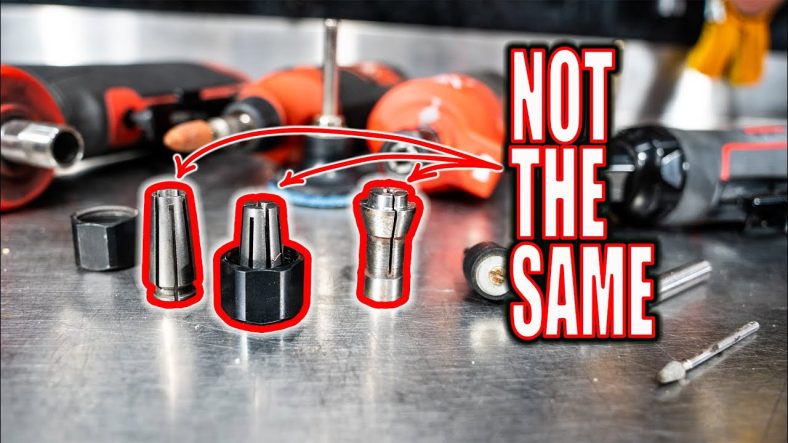

Die Grinders rotary tools corded rotary Tools cable driven rotary tools they all Have something in common even routers They have collets what are collets well We're going to talk about them [Music] So this video actually started from a Question we got to ask or a statement That one of our awesome viewers brought Up and that was they wanted to sharpen Some chainsaw blades and so they bought Some carbide bits off of I think it was A steel carbide bit but they wanted to Use a rotary tool to do it or a die Grinder and specifically I believe it Was this 90 degree die grinder that he Bought from Milwaukee or bought from Home Depot or Acme Tools or somewhere And he wanted to use the carbide tools Or the carbide burb bits in this tool However there was one big huge problem That really wasn't a problem if he just Knew and to be honest Milwaukee hasn't Done a great job educating that this is A simple problem to fix and that was This is a quarter inch die grinder in Other words quarter inch accessories fit In here and the carbide burbit was a Eighth inch Tool accessory and you see that doesn't Work out too well no matter how tight You get that it's not going to work so With that let's dive in and take a Closer look at different collets how

They work and how you can address that Exact situation okay let's have a little Collet talk and what does it call it Well a collet is one of these things Right here and basically it's just a an Insert that goes on the inside of a some Type of rotary tool or what we would Call a die grinder which is pretty much Everything we have here but there's one Thing that's important to these actually There's a couple of things that's very Important about these number one what Size collet are you running so this is An eighth inch collet meaning that Things with an eighth inch shaft will Fit in there and then basically when you Have the outside collar on it squeezes That collet and keeps that tool secure Now a quarter inch collet Which would be in most of these other Than this one this is an eighth inch Tool so it will only fit eighth inch Collets Other tools Take this die grinder apart here and you Can see here's a quarter inch collet and This is going to fit quarter inch tools So like this tool here you can see the Quarter inch is going to fit in there And what's going to happen is as this Collet as this collar on the collet Comes down and squeezes on that Accessory it's going to lock that into Place

And obviously the cone The cone right here on this plays a big Role And going on the insert there and Squeezing down now why am I going Through all this well because I'm fixing To show you something And then once that squeezes down It locks that into place now that's just A regular collet And if I loosen that I can bump that and then pull that out It'll easily kind of give it up and I Can pull that out Now And again I'm going to get to where We're going here in just a moment these Milwaukee Tools as well as you'll see This in lots of routers and some of the Die Grinders but most of your air die Grinders your typical stuff around Automotive body shops things like that Is like I just showed very simple collet Once you loosen the nut you can Sometimes if it's stuck just kind of Bang the tool or the accessory and it'll Loosen up however Milwaukee uses what They call a safety collet And so which by the way you see my Wrenches here So these two wrenches doing these One-handed are a pain sometimes so I Took this and I actually bent it and When I bend it it broke so that's why I

Re-welded it but you see I've got a 90 Bend on it and I can put it on here and Hold it with one hand while with the Other hand break this free so now so I've broken this nut free And this tool is inside here I cannot Move that tool now I could put that Device and try to pull it out it's not Going to give that up I could bang it And ruin that carbide tip or if it was Another type of tool I could bang it and It's not going to loosen that and you See that nut is free right there the Shaft is not turning but the nut is free And it will not let go of that accessory Of that bird bit of that carbide tip Because it's a safety collet and again You see how loose it is I can turn it With my finger no problem at all okay so What you have is you break it free the First time and then you give it a couple Of turns and it's going to get hard Again and so you have to break it free a Second time People argue with me on this all the Time and I'm telling you it's the case And watch this so now break it free a Second time and now look at this Now the accessory is relieved and it'll Pull out of there so that's the Difference in a lot of the newer battery Powered or cordless die Grinders is There using safety collets which again Have been used in routers for quite some

Time but most of the people that use air Dye grinders do not see this and they Get frustrated and sometimes even ruin The tool trying to get it out so with a Safety collet loosen it twice you loosen It back it off a few turns it'll get Hard again loosen it again and that's When it actually releases the tool now Let me pop this out of here And where are we going with this well Initially basically one of our viewers Came and said hey I bought one of the Milwaukee rotary tools and I believe he Was wanting to sharpen chainsaw blades Well the chainsaw burbits if you will Came in an eighth inch shank so much Like you see here this one's a stone but We get it well that eighth inch is not Going to fit in that quarter inch well Basically he thought that well I need to Get a different tool so he bought the Smaller M12 eighth inch rotary tool but He really wanted one of these tools here And I said well you really didn't have To do that You could have Bought this right here And this is A collet from Milwaukee four eight inch Shakes so you can see I can put it on Here So what I can do I can take this eighth Inch Call It screw it in there

I think one of my eighth inch shank Tools Or accessories and put it in there And clamp that down And now I can run any of my eighth inch Accessories now you can also get I'll Throw a a picture of one up there you Can buy them all over Amazon or anywhere Else basically it's something that Basically slides onto the shaft of this And uh basically offers it a quarter Inch shank so it will go in there and And actually go into your um into your Quarter inch collets and lock into place I don't like using those that's like an Adapter I like having an actual eighth Inch collet or a quarter inch collet and It's going to do a better job at making Sure everything's centered and balanced And everything else and in this case It's made for this tool versus something Just being on the shank Now I also wanted to show You see that the the design of this Collet versus this one here that goes in That air grinder much different you can See the cone the degree on the cone much Different so don't go and try to use Another or your typical air dye grinder In one of the Milwaukee or one of the Cordless die Grinders because it will Not work and it will bind up and you see Also right here on a close-up you can See that there's no step or basically

There's a step down and no ring that Locks this collet into the And I'll just show you here So this collet doesn't lock into that Collar you can push it up there and it Just falls out And that's the beauty of this is this Actually kind of snaps into place Into the collar you can see it it Kind of wobbles all around until I press It in and then it pops in and locks in And that's part of that collet Locking Collet System is when you back that off That second time it's actually pulling That off the shank and unlocking that From the cone and from the actual shank Of the accessory So this will run you I believe it's About 20 bucks we'll have a a link in The description the other adapters I Think you can get for you know probably 10 bucks and get a few of them so you Can go that route as well but you can Definitely run eighth inch accessories In your typical quarter inch die grinder But again you're changing out the collet And I would recommend if you buy one of These tools go ahead and buy your eighth Inch with it and then you've got it Ready and available so if you do have a You know specific eighth inch tool that You're wanting to use you can easily Swap those out and also Highly recommend you doing this this is

So handy to have so that I can just hold This tool and it'll work on my Straight Die grinder it'll also work here On the 90 degree die grinder as well I Can tighten it there or I can flip it Over And I can lay it right there against the Tool and then with one hand easily be Able to loosen those collets and again There you go so even though it it's Loosened the first time it's not going To give that up But yeah break that free a second time And there you go No problem All right well I hope that we have Filled you in on safety College on Regular collets and a couple of hacks That we've done that I'm telling you This wrench idea I think we've posted it Three or four times on Instagram and It's always a huge hit such a simple Idea rather than two straight wrenches When you're trying to you know hold the Tool and and work both of those the the Nut and the shaft at the same time now You can easily just take that put that Alongside the tool hold it with one hand Break it free tighten it up so that is a Great idea right there of either bending Or it may break on you until you may Need to weld it but if you get one of The the cheap wrenches they will bend And then also understanding how to use a

Safety collet I'm telling you I made a Video on this uh probably I don't know Like two years ago and we've had Multiple people comment on that where They say oh we've put it in a in a vise And banged it with a hammer and Everything else trying to get the bits Loose because they didn't know that you Actually have to loosen it twice I know It's not really loosening it twice but There's two hard spots break those free And then these bits just slide right out Hey let us know if you have any other Ideas you'd like for us to tackle also Let us know if you like this video or Not because if you hated it well then Give us a thumbs down but be sure to Follow us on Instagram Facebook Twitter And even Tick Tock have a great day keep Smiling