Upgrading my sturdy 2×4 workbench with storage drawers and clamp storage.

Thanks to Woodcraft for sponsoring this video! Get woodworking supplies at

🎥 What to Watch Next:

Build a Sturdy 2×4 Workbench –

5 Mistakes Buying Plywood –

Mobile Wood Storage Cart –

How to Build a 3 Drawer Cabinet –

➤Plans from this video:

Storage Upgrade Plans Coming Soon!

Sturdy 2×4 Workbench –

Modular Garage Cabinets bundle (Save 30%) –

Mobile Lumber Cart –

➤Join the Builders Club!!!

More content, early access, FREE plans, video credits

➤Tools/Supplies Used (affiliate):

Wood River Panel Cart –

Kreg Panel Carrier –

Kreg Track Saw –

Kreg Foreman –

18” Drawer Slide –

Mirka Deros Sander –

Inventables X-Carve CNC –

Easel Design Software –

TotalBoat Halcyon Clear Poly – (2022 10% off code: FIXTHISTB)

ISOtunes Bluetooth Hearing Protection – (10% off code: FTBT)

3M Xtract Sandpaper –

➤Support the FTBT Channel:

Buy FTBT Woodworking Plans:

Buy FTBT Merch:

Links to My Tools & Gear:

Subscribe:

➤Thank you to these partners for supporting my channel. Go check them out!

Woodcraft:

Kreg Tool:

ISOtunes: (10% off code: FTBT)

TimberlandPRO:

➤FOLLOW ME on Social Media:

Instagram –

Facebook –

Twitter –

Pinterest –

Music Licensed through Epidemic Sound – Get a FREE month:

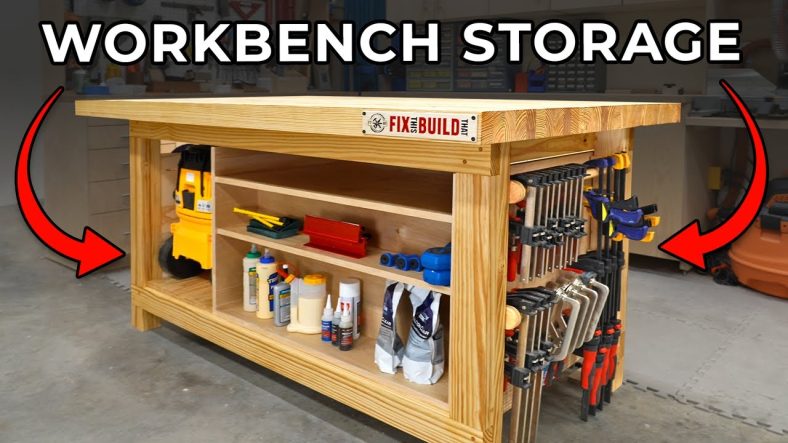

I just built this awesome workbench But it is wide open down below

and I really need that for storage. And also it's attracting some unsavory

characters. Rodriguez! Hey, people trying to sleep down here. Chuck, who are you? George Costanza.

Whatever, man. Let's build something awesome. I'm thinking some drawers, at least

on this side of this lower cabinet. And then on the end, I can hang some of

the clamps and things that I use the most. But maybe the thing I'm most excited about

is getting rid of this whole situation. The dust extractor for my sander

and the hose that lives over here Underneath the wing of my table saw

This is a horrible place for it Because it sticks out

and it's kind of all janky here anyway. Plus it's obviously a tripping hazard. I'm going to get started

by making a box for those doors That are going to go underneath And I'm going to have a little cool shelf

on the top to help Catch things that go through these dog

holes. You'll see what I mean. And just a bit,

I've got the panels for the cabinet All cut up

and now I'm going to put them together And this will be the box

that'll just kind of house everything. And then I'm going to add

all the accessories around it. I'm going to be using Pocketable joinery. So I cut some of those over on the foreman

and now I can put it together. But first of all, look at

how big this bench is. I can fit everything on here. This is exactly why I built this. I don't know. I slept that. I couldn't have done this big of a cabinet

on my old workbench Without having,

like a piece of MDF on the top. Where are my clamps? There, on the floor. Go. And this is what we're solving today.

All right, So I've got a center divider

because I want to base of drawers, And then I'm going to have another piece

that goes on top. And this is where

the cool little tray will be. So I have the piece also for the front,

because this is not for depth. And I'll use these two pieces to center up

that top shelf, Make sure that it is

parallel to the bottom. I'm just about to screw

this thing together. And then I saw this at Just a big nasty void

right in the plywood in. This is the type of thing

that would drive me absolutely insane Because I like a nice,

clean, perfect look. Everything has to be perfect,

but I'm trying to get better and, Well, no mistakes were made

and they obviously made a mistake here. So We're going to leave it. Maybe Now just slide it in the center divider. I've got a couple of spacers

and I can just put these In between the side here

and then make sure that center divider Is right

smack dab in the center of both sides. And here's a little trick For clamping the center dividers because

it is set back about six inches or so. I can't really put a clamp here

and get pressure, so I'll just take it A little bit longer board

and just wedge it down in there. And now because I have these spacers

in here, it will push up against there and Be tight. I can screw in place. All right. I get the carcass all put

together. Let's give it a little test fit Now. There we go. Perfect. Now, I do have this little panel

that's going to fit right inside here. And so still not exactly sure What I'm going to do,

but this should be recessed back there. So I think maybe I could make this into like a little tool

or maybe even have something else on it.

I don't know,

but I'm gonna leave it off for now. And while I've got the box down here, I want to focus on the Sander area

down here for the mock up. And so I went ahead and cut

a little piece of ready out of pine, Had this left over

from the plywood versus MDF test video. Now, if I just slide this in And all the holes coming out the front,

so I'm going to stick It in here in the backside. Oh, it does not fit. All right. Looks like this little piece

right here is sticking out too far, So I'm just going to remove it. There we go. Oh, all right. This worked out perfectly. It fits in there so nicely,

but I still have This whole thing of hose

and the actual sander itself. So I'm thinking I'll make

some kind of little hook here. Maybe something like this. I measured the area and I figured out

I can put a little board there To keep the hose out of the way

and have a little spot for the sander. All right. I've got some parts here,

and I think they turned out pretty cool. And I just took these measurements

and I put them into easel, Which is the design software

that runs my X car of CMC, and I design Some parts that I can stack together

to hold the hose on the side of the bench. Then I took them over to the x calve

and had to see and see, cut them out. And I love using C and C

for this type of work for making custom Tool holders and such. It is awesome. So here's what I came up with. I have a little bass piece and this is

solid, so I can mount it to the side. And then I cut a bunch

of these little spacers Which are just little semi circles. And so as I put these all together,

that will allow me enough room For the hose to sit in and to make sure

it doesn't fall off the end.

I made this little little guy,

which kind of looks like an alien, But when I put it, I realized that

it's a little bit too big for the hose. So I made this other one that is slightly

more offensive, but more effective. No. And so That way I could just drop the hose

right over the top of a single piece. And I think this is going to work. Awesome. And I also cut out this piece

for the sander, And this just has a little semicircle

in it. And I did route into the back

a 45 degree chamfer, And then I put a few quarter

inch spacers on the back To hold it off of the board

so that the center of it nicely in there. So now I'm just going to go ahead

and glue. And meanwhile these together and then

we can mount everything on the side. I put a little finish on this guy

and now I can Just screw it in place. All right, now let's give it a test. It lets you know this guy works. He has. That is perfect. So all out of the way

and within the bench. And the next thing I want to bring to

the workbench is my small clamps. I have them all stored over here

behind the drill press. They're kind of hard to get to And I use them all the time, so

I want to put them over here on the side. But that's not the whole story. There's more clamps and I'm embarrassed to show them to you,

quite frankly. This is one of the best kept secrets

on my YouTube channel. And that is what the underside

of the old workbench look like. And here it is, Just a hot mess of clamps and bench

dogs and work holding. I don't know why I never organized this Or built anything down here,

but I just never did.

But now we're going to solve it. I'm going to take all these clamps over

and start laying them out And see what we can figure out. Are we got a bunch of my clamps up here? I'm sure there's some stragglers around

the shop, but this is most of them now. I don't think I'm going to be able

to fit everything, But I did cut a little sheet that will fit

in that exact opening on the side. So what I'm going to do now

is start stacking these on here And just kind of see what kind of layout

I can get and see how many I can fit In this space. Okay. After far too long trying to figure out

exactly what I wanted on this, I just decided to kiss it instead. That is to keep it simple. Stupid. Or was it keep it stupid, Simple. Whatever it is, I'm going to make it totally simple

and just use a couple one inch dowels. Because what I realized Is if I make specific things here,

then I don't have a lot of adjustability. But pretty much all of these clamps

can just hang right on a dowel rod. So I don't have to have specific kinds

and specific places. I can just hang whatever I need to,

and then the longer ones can hang down And I can just scoot ones back and forth,

have some long ones there on the side Because they weren't really fitting real

well in this layout. And if I don't like it,

I can always adjust it later. There's going to be a Much simpler solution as far as the setup

and to make the brackets, I just get these little guys where I'm

going to put the one inch dowel in there. And I did cut these over on the X carve

because it makes stuff like this So fast and easy. So I've got this cut down there. It's going to put the one inch down

into the holes. Now I've got the dowels right in here. There we go.

And I will secure these with some screws. And now my clamps can sit right on there. All right,

let's see how everything fits in here. The long ones can go down below. Oh, and these even just that. I can maybe stack these like that. Well, it's not perfect,

but I like how much it's holding, And I have to see as I use it, If I need a little bit more headroom

in between those lower ones. And if I like having these taller ones

kind of staggered in between each other Down here at the bottom. But for now, this is going to work great. I'm feeling good about the sides

and it's time to attack the drawers. So what I've done is I pulled out

some of the things that I think I'm going to be using the most

at the bench, including some sandpaper. And this is the three extract. This stuff is awesome. I'm sure you've heard about it,

but I have some screws here, Some specialty clamps,

as well as some clamping squares. So this is just kind of representative

of what I might be using at the bench. So what I want to do

is kind of check the heights And then make the drawers specific

for what I'm going to be using it for. So we've got maybe three

and three quarters. That's also right around

three and three quarters. These are just a little bit over

three inches and these are only maybe two. So it seems like if I make some drawers

that are about four inches Deep,

that's going to work really well for here. Now, the thing I have to work around

is the opening That's already in the cabinet,

so that is about 17 inches. So I don't think I could fit

four of those four inch drawers in there. So I'm gonna have to play around. So maybe I'll make that top one

even a little bit smaller And have that for Some of the thinner things and then have

the larger drawers behind it.

But I'm going to play around

with the dimensions a little bit And then I'll go over and start

cutting some parts. All right. I've got all the parts laid out

and they're ready for assembly. And I did decide on doing three drawers, Two smaller ones,

and then a large one on the bottom. Now I went ahead And cut all the parts on the table,

so I did a little bit of joinery over On the foreman, but I did something

a little bit different. I pre finished everything

with the varnish. I used a total bowl Halsey on clear And put it all over everything,

including the bottom. And I was a little concerned

about doing this Because it will be glued to the bottom And I want to make sure it's a wood,

the wood connection. But I just left a little strip around

there that didn't have any finish on it. So I think this is going to be great

and it's going to save me a lot of time. And I don't have to like get all the goopy

mess out of the corners anymore. I like this. We do have plans available

for the workbench And we're going to a combo

where you can get the storage as well. Link down to the description

if you want to go check it out. All right, The drawers are ready to go. And my voice is a little deeper today

because apparently I'm coming down With something. But we'll finish this today and be done. I went with a Goldilocks approach here. I went with a larger drawer for the bottom

kind of that foreign store That I had talked about,

and then even smaller one for the top. I think that's going to work out

really well. But if you don't know what size To make your doors like,

I've made dozens of drawers And I still kind of waffle

when it comes to sizing them. Just, you know, go for it. And you can always remake the drawers

if you need to.

Not a lot of wood involved in that. So don't feel like you're trapped. Just make something and move forward. But now it's time for me to move forward. I'm going to pull up that cabinet up here

and get these guys mounted. I've got some full extension lines here. I cut a few spacers

to help me install these along the way, And I'm actually going to turn this up To make it easier

so I don't have to fight gravity, Which is a great tip

that I picked up from Mark's bag. No Load whisperer. If you need your slides or other things For your projects,

you can check them out at Woodcraft. Who's the sponsor of today's video? Now Woodcraft is a woodworking supply And hardware store,

and they have everything That you could need to do

your woodworking projects, Anywhere from the large machineries All the way down to the hardware,

the finishes and everything in between. You can check them out at over

70 locations throughout the US or online At TRANSCOM, if one is not local to you,

A big thank you to Woodrum. Go check him out if you need something

for your next woodworking project. All right. That is the last drawer. These look great.

This is going to be awesome storage. If you want to know how I install drawers,

I've got a bunch of cabinet videos. You can go check them out.

I'll have some of a link down below. You can get all the details on that. But right now I'm going to switch

over and start making this top drawer, Which is going to be like a catch All tray that I want to be able

to access from both sides. So it's not going to have door

slides, it's going to be friction. And I'm not sure exactly

how much do the runners But I'll start out by making that drawer.

Okay. Change of plans. I just spent the last hour going through What I'll call a perfectionist spiral

and maybe a death spiral. I don't know, something like that. But I was looking for material to make

that top drawer, and I couldn't find any. At least I couldn't

find the stuff that I wanted. So for this drawer and top,

I want the grain To match the rest of the drawers. Oh, no, no, no, no. Oh, thank goodness

this is going the right way here. Oh, I see. This is the only piece that is long enough That the grain is going

in the wrong direction. Oh, and having the grain

go vertical across That wide span, the door

just started giving me heart palpitations. And that Led to me thinking about that

exposed plywood edge. And so I came back

and I put edge banding all over it. I just Couldn't help myself. I had to do it. So I'm going to leave

this open is going to be a shelf Instead of a drawer,

and I'll see if I like that or not. And I can always add that drawer in later. But in the meantime, on the backside,

I've decided I'm going to do a shelf From there. And so I do have this one piece

that fits right in there. I'm going to edge bang this guy

and then install that And it'll make me feel good. And in case you're wondering,

it is much, much easier to edge ban Before you assemble. So if you know you're going to do it

anyway, just do it beforehand. All right. I took the drawers out

so I can put in this back piece here

And it should slide right in and register

against that center stuff, Do a few adjustments and I can attach it

with screws from the back. I put a few pocket holes on the bottom

and I got a little spacer And that's where

I'm going to mount this bad boy. So this should be just enough room

to fit some finishes Or glue or bottles or even a drill

if I wanted to put it somewhere. Right, See if I can slip this thing

back down here. Oh, boy, that's heavy. All right. That's a good fit. All right.

I secured it in place with some screws. Now I can get the drawers in here.

This thing, load it out. I think I like this shelf,

and I just loaded up a few random things. Also, this little top shelf

maybe be good for just clamps. Put that in during the glue up and, you

know, lose everything you put in there. I did add that power strip

and it's right here on the front. So I can plug in the sander. And this turned out great, but I wonder What Chuck is going to think. Well, la tee frickin da, he did it. Look at that thing. Where am I supposed to nap?

That's pretty cool. I bet it took him about 3 hours

to figure that out, though. Whats it got on that other side. He got six drawers in here. Got a big one, a small one. Think I can put my stretch Armstrong

right in there. He's even got a sander on there. Hey, well, back at you, buddy. If you want,

check out how I built this workbench. I got the video cued up for you

right there. And we do have plans available

for the bench and the storage. A big thank you to the FTBT Builders Club. And until next time, guys,

get out there and build something awesome.